Quality Management Module

Tradictional manual inspection requires a lot of time and manpower, and the judgement criteria vary from person to person, making it difficult to keep up with the speed of the production line. This product uses AI image recognition to automate the inspection process, allowing enterprises to improve product quality, reduce defect rates, and after-sales costs.

Defect Detection

Apply AI image recognition technology to automatically detect product appearance, successfully applied in the automotive and components, electronic components, electronic materials, injection and metal processing industries.

Object Identify

Identify ojects used in the production line, provide specification information, and apply to product incoming, warehousing, and shipping to grasp the current status of production materials.

Size Measurement

Size measurement is performed accurately through AI image recognition technology, suitable for industries that require precise dimensions to meet product specifications and customer requirements.

Image Position

More precise control and operation by accurately positioning the target object through image recognition technology.

Anomaly Alert Management

Notify abnormal conditions in a timely manner, respond quickly to abnormal situations, and improve production safety.

Visualized Management

Clearly display production data and processes, achieving transparent and precise production operations management.

Easy Installation, Simple Setup, Quick Validation

No-Code AI Model Creation

Using the Google Colab, enterprices can easily operate and create AI models that meet industry needs.

Multiple Module Options

Provides a variety of module options to improve development efficiency and meet various needs.

Model Creation with 30 Images

Through the automatic image labeling function, a large amount of labeling time can be saved. It also provides image generation and augmentation modules to enhance the accuracy of defect recognition and overcome the problem of insufficient sample size.

Small Batch Detection

Create object, defect, and limb recognition models through pre-trained models and small batch data, with up to 100 model optimization options, suitable for small batch and diverse detection production.

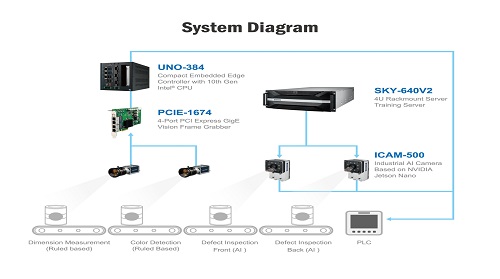

Edge Deployment to Reduce Costs

Deploy the model on edge devices after lightweighting to reduce costs and improve execution efficiency and security.

Cloud Remote Maintenance

Provides cloud architecture for remote problem-solving and system maintenance, improving development efficiency and system reliability.

Success Story

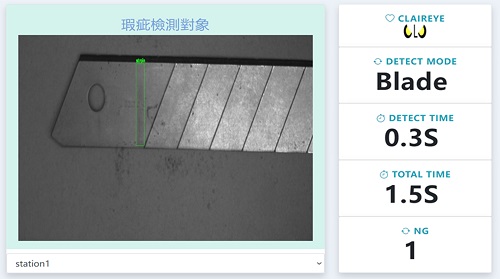

AI defect detection system for improving the shipping quality of paper can factories - automatic inspection, no manpower required, and transforming sampling inspection into full inspection.

Read ReportSuccess Story

Using deep learning and computer vision, Claireye Intelligence accurately and efficiently identifies good and defective products.

Read ReportLet's Get In Touch and Discuss Business Opportunities

Contact us if you have any questions about our products and services, and we will arrange for industry experts to consult with you.

Contact Us